February 10, 2022 | Memo

Elemental Strategy

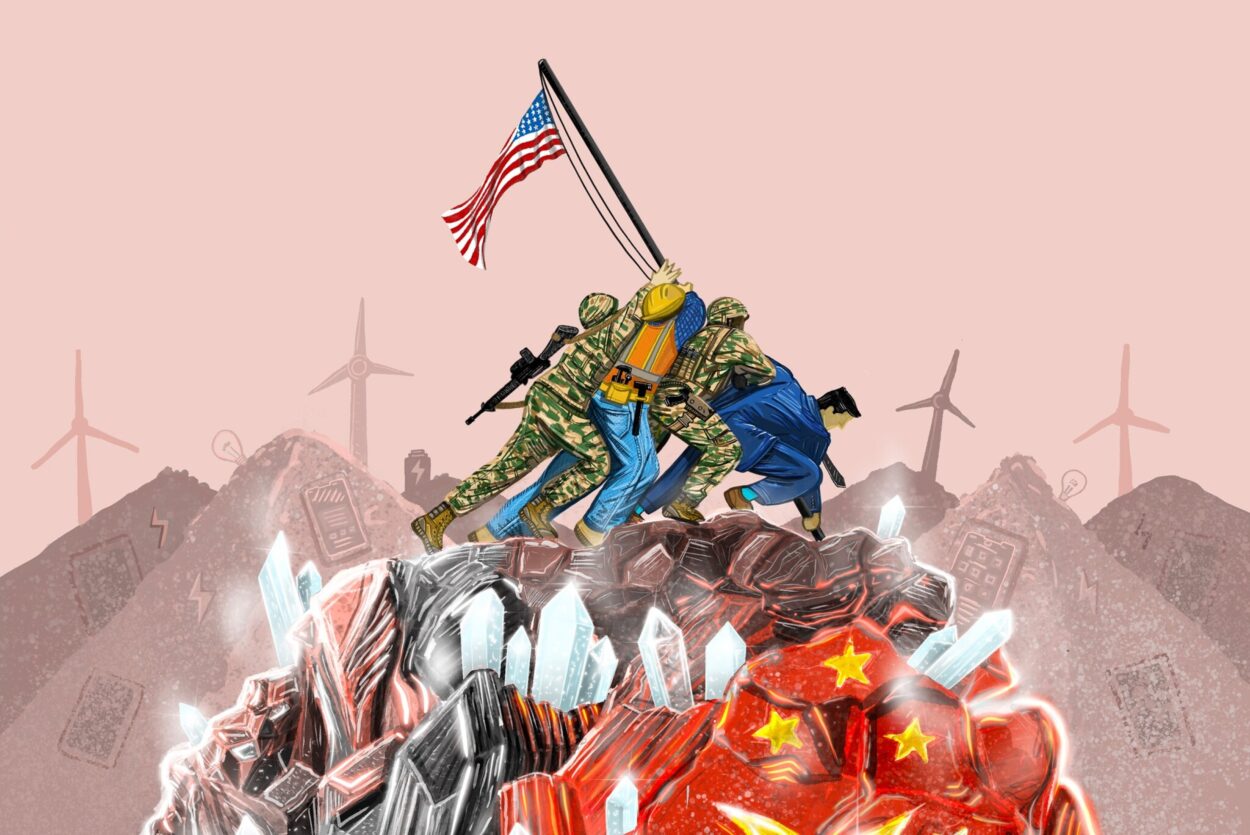

Countering the Chinese Communist Party’s Efforts to Dominate the Rare Earth Industry

February 10, 2022 | Memo

Elemental Strategy

Countering the Chinese Communist Party’s Efforts to Dominate the Rare Earth Industry

Introduction

“The Middle East has oil and China has rare earths,” Deng Xiaoping said in 1992, four years after China’s output of rare earth elements had surpassed that of the United States.1 Since that time, Beijing has systematically built a dominant position across the supply chain for these critical elements, whose unique electronic and magnetic properties make them indispensable for both military and industrial purposes. By 2018, the U.S. Department of Defense (DoD) had concluded that China poses a “significant and growing risk to the supply of materials deemed strategic and critical to U.S. national security.” Not only does Beijing dominate upstream mining of critical minerals, but it is also “increasingly dominating downstream value-added materials processing and associated manufacturing supply chains, both in China and in other countries.”2

America’s long-term success in its economic and security competition with the Chinese Communist Party (CCP) depends on securing U.S. supply chains and activating the U.S. private sector. Washington’s efforts to ensure the security of supply chains for rare earths and other critical minerals have been thus far insufficient as the United States heads toward increased global competition with the CCP. To date, the U.S. government’s approach has consisted of piecemeal and ad hoc responses. Meanwhile, China has consistently gained strategic advantage. Ultimately, the U.S. government needs to pursue targeted measures based on a well-defined, holistic strategy to immediately protect military-specific supply lines, while embarking on an ambitious program to unleash the power of U.S. and allied private-sector forces to overtake the commercial upper hand currently enjoyed by the CCP. Thankfully, a consensus is building in this direction.

Illustration by Daniel Ackerman/FDD

Illustration by Daniel Ackerman/FDD

On February 24, 2021, President Joe Biden issued an executive order launching a 100-day review of supply chain risks across the U.S. economy.3 The review concluded that established policy related to domestic production is at the core of America’s supply chain weaknesses, including in critical mineral supply chains.4 Congress’ 2021 Consolidated Appropriations Act also tasked the director of national intelligence with studying critical mineral investments undertaken as part of China’s Belt and Road Initiative.5 The bipartisan 2021 infrastructure bill included a range of critical mineral supply chain appropriations as well as a clear statement that “critical minerals are fundamental to the economy, competitiveness, and security of the United States.”6

Assessments of supply chain security often call for measures that extend from “mines to magnets” — that is, from the point of extraction to the finished product.7 Yet Beijing’s industrial policy seeks to ensure dependence on China that begins before extraction and extends beyond production. Beijing also seeks to control the pools of capital at every stage.

China dominates the supply of “heavy” rare earths through both domestic investment and access to extraction activities abroad (for example, in Myanmar).8 China also dominates the technologies, equipment, and capacity needed to separate and process rare earths and to produce rare earth permanent magnets. This stranglehold cements CCP control over the rare earths that are most critical and have the highest value-added. On top of that, by controlling key pools of capital, Beijing ensures that the rare earth industry continues to depend on financial or operational endeavors controlled by China. This is the case across rare earth production, separation, and downstream component manufacturing.

In other words, China’s dominance — in both heavy and light rare earths and in other critical minerals — is not simply a function of resource control. Beijing maintains industrial leadership, and even control, in the manufacture of specialized equipment, in later-stage production, and in the financing necessary for capital-intensive processes across the value chain.

Chinese sources — ranging from official government statements to industry and press commentary — frame dominance across the rare earth industrial chain as a strategic lever in today’s great power contest. That effort is part of a broader Chinese strategy that converts economic and technological integration into global power projection. Without rare earth elements, the Chinese press has observed, the “U.S. military’s technological advantage will be zero.”9

The United States already faces dangerous disadvantages, since rare earth elements and the permanent magnets that incorporate them are vital across national security and commercial use cases.10 Today, dependencies on China for rare earth elements affect the production of everything from F-35 fighter jets to medical equipment.11 Given their importance for electric vehicles and wind turbines, rare earth elements are also integral to current efforts to transition to cleaner forms of energy and transportation.12 Industry observers project that the market for rare earth magnets will double within the current decade.13

Chinese sources consider the current era of strategic competition to be one that is no longer a competition among individual companies, but rather a competition between supply chains.14 Dominance over global rare earth supply and processing provides Chinese players — commercial and military alike — with leverage that no rival can replicate.

The first step in remedying this situation is to recognize and understand Beijing’s strategy. Only then can U.S. policymakers develop and implement a systematic response to ensure the United States has secure and trusted access to the rare earth elements, processed oxides, metal alloys, and permanent magnets necessary for U.S. national and economic security.

A responsive U.S. strategy must develop supply lines, production capabilities, and end-product value chains wholly independent from Chinese influence, supply chain leverage, and capital. This effort must prioritize the role of the U.S. private sector and its advantages vis-à-vis Beijing. The United States, its allies, and private-sector partners must also recognize that Chinese control is not always direct or obvious: Enduring solutions require taking a fine-tooth comb to the entire ecosystem — and to the entire network of players involved.

A winning U.S. strategy can be distilled down to four mutually reinforcing lines of effort. First, DoD should lead an aggressive stockpiling program to guarantee access to sub-systems, permanent magnets, and raw materials necessary for U.S. military programs. Second, tax incentives should be the central driver of the U.S. government’s efforts to activate the power of the American private sector and to make full use of America’s enviable domestic endowment of light and heavy rare earths as well as related production capacity. Third, the United States should work with allies and partners to develop trusted supply chains and to position themselves more competitively. Finally, the U.S. strategy should leverage both economic and military tools to impose costs and introduce inefficiencies in China’s rare earth sector and corresponding industrial policy.

How We Got Here: China’s Historical Emphasis on Rare Earths

The People’s Republic of China has focused on rare earth extraction, processing, and downstream applications for as long as it has existed. “Scientists and national leaders foresaw the importance of rare earths at the beginning of the founding of the People’s Republic of China,” wrote Huo Zhijie, a scholar and industry researcher affiliated with Inner Mongolia Normal University, in 2019. In 1953, under the guidance of national science and technology policy, the Chinese Academy of Sciences and the PRC Ministry of Metallurgical Industry jointly launched construction of China’s first rare earth plant, the China Baotou Number One Steel Rare Earth Factory. That plant was completed in 1959. Ten years later, Beijing assigned the plant to state-owned champion Baosteel. “This marks the start of China’s rare earth industry,” explained Huo. In 1963, the People’s Republic of China established the Baotou Metallurgical Research Institute to both research and produce rare earths.15

In the years after Deng’s famous quip that “the Middle East has oil and China has rare earths,” the country continued to export its rare earth products at low cost to “meet the needs of U.S. industry and national defense,” as one Chinese industrial planner noted it in 2018. This rendered the United States dependent on Chinese sources of these products.16 During this time, China also targeted downstream U.S. companies in the rare earth industrial chain. In 1995, a consortium of Chinese state-owned companies purchased a majority stake in Magnequench,17 a General Motors subsidiary that pioneered, and held a dominant role in, the manufacture of rare earth magnets.18 In September 2001, Magnequench’s U.S. production lines shut down as the company’s stewards gradually shifted production to China.19 Two years later, the company transferred its research and management functions to Asia.20

The early 2000s marked a turning point in China’s rare earth strategy. The new millennium heralded the development of novel rare earth mining and processing technologies as well as the discovery of new rare earth sources. Global prices dropped. Beijing’s market share shrank. Concerned by these trends and by corresponding decreases in its influence over international markets, Beijing worked to buttress its strategic position at home and abroad. In 2006, Beijing imposed export quotas and domestic market controls over the industry. In 2007, China’s Ministry of Land and Resources heightened regulation of rare earth output. The following year, Beijing began integrating and consolidating its rare earth industry. In 2009, the Ministry of Industry and Information Technology (MIIT) launched the “Special Plan for the Development of the Rare Earth Industry and the Policy for the Development of the Rare Earth Industry.”21 MIIT also joined with the Ministry of Commerce in strengthening China’s export management system for rare earths. “The quota allocation method,” explains Cai Enze, a former Chinese political leader and industrial planner, “controls China’s rare earth exports and prevents the loss of resources.”22

The next year, in 2010, the world witnessed the coercive power that China had accumulated through its position in the rare earth industry. Beijing had solidified its industrial chain and could deploy targeted export restrictions to influence pricing and, in turn, corporate policies globally. China’s political leadership was prepared to take advantage of this position for geopolitical purposes. During a diplomatic standoff with Tokyo over control of the Senkaku Islands,23 Beijing temporarily halted rare earth exports to Japan. Tokyo’s then-minister of fiscal and economic policy ceded at the time that “the de-facto ban on rare-earths export that China has imposed could have a very big impact on Japan’s economy.”24 This prompted the United States, Japan, and the European Union to launch a joint World Trade Organization (WTO) case against China in 2012.25 While the WTO ruled against China in 2014 and obligated the Chinese government to roll back its rare earth export quotas,26 CCP industrial policy replaced quotas with consolidated state control of the rare earth industry. In effect, the CCP adjusted its policy to function by virtue of influence over production through tightly policed annual production ceilings.27

Around the same time, Beijing launched a series of high-profile national-level industrial plans, including the 2011 “Strategic Emerging Industries Initiative” and, four years later, “Made in China 2025.” Wang Denghong of the Chinese Academy of Geological Sciences noted in 2019 that rare earths “play a key role” across emerging strategic industries. These industries include new-generation information technology, high-end equipment manufacturing, “new materials,” biology, new energy, new energy vehicles, energy conservation, and environmental protection.28

Following the 2014 WTO ruling against China, the People’s Republic of China consolidated the rare earth industry according to the “Guiding Opinions of the Central Committee of the Communist Party of China and the State Council on Deepening the Reform of State-owned Enterprises (2015).” These policies increased state control of strategic resources. Beijing consolidated six major rare earth enterprises, all state-owned: Chinalco, North Rare Earth, Xiamen Tungsten, China Minmetals, Guangdong Rare Earth, and South Rare Earth Group. Beijing also directed its champions to capture both upstream resources and downstream applications.29 The Ministry of Commerce’s 2019 “Catalogue of Export License Management Goods” announced that special licenses are required to export any rare earths from China.30

These industrial plans follow the tradition of the CCP’s “Two Markets, Two Resources” strategy.31 First cited in official Chinese policy in 1981, this strategy frames Beijing’s entire ecosystem of economic and security plans; foreign markets become dependent on China, while China remains relatively autonomous.32

Alongside those plans, Beijing also developed policies focused directly on rare earths. On May 10, 2011, the State Council, the chief administrative authority of China’s central government, issued “Several Opinions on Promoting the Sustainable and Healthy Development of the Rare Earth Industry.” The opinions laid out a plan to establish a standardized program and monitoring system for China’s rare earth industry. They also required, for the first time, the establishment of a rare earth strategic reserve system. The State Council explained that this system would include “a combination of national reserves and enterprise (commercial) reserves.”33 In 2012, Beijing launched the “Measures for the Management of Special Funds for the Adjustment and Upgrade of the Rare Earth Industry.” This included a special fund to support rare earth mining and processing as well as research and development (R&D), promotion of standards, industrialization of new technologies, and construction of public technical service platforms.34

In 2016, then-Premier Wen Jiabao chaired an executive meeting of the State Council to study and promote the rare earth industry. The result was the “Rare Earth Industry Development Plan (2016-2020),” issued by MIIT in June 2016. “The major industrialized countries attach great importance to the strategic value of rare earths and the development and application of related fields,” the plan observed. It laid out a program to further consolidate China’s rare earth industry, “strengthen the protection of rare earth strategic resources, standardize rare earth mining, expand development of rare earth high-end applications, and give full play to the strategic value and supporting role of rare earths.”35 The plan stipulated that the annual output of rare earths would not exceed 140,000 tons.36

The plan also called for the strengthening of “rare earth international cooperation.” Beijing would “promote rare earth enterprises to Go Out and cooperate in the development of overseas resources and deep processing of products.” The Chinese government would also “encourage rare earth companies to cooperate with overseas new material companies and technology research and development institutions.” In doing so, Beijing would internationalize its rare earth standards and further strengthen its grip on the industry.37

China’s Dominance of the Industry Today and the Challenge for U.S. Policy

Chinese leaders continue to frame rare earths as a viable tool for coercive geopolitical effect, including vis-a-vis the United States. Chinese sources are explicit about how Beijing can use rare earths coercively in response to geopolitical disputes as a complement to China’s political, military, and diplomatic levers of power. A Chinese government-funded project on rare earth industrial policy concluded in 2019 that China should not rule out using rare earth exports as leverage amidst trade tensions with the United States.38 Chinese press sources touted Beijing’s decision to sanction Lockheed Martin in July 2020 as a step in this direction.39 Chinese scholar Jin Canrong has continually emphasized that Beijing’s ability to restrict rare earth exports and manipulate the rare earth market amounts to a “trump card” that can bankrupt U.S. rare earth operations, greatly diminish the viability of downstream industrial development, and shift China from a position of net import dependence in key areas (such as semiconductors) to a position as a market-leading net exporter.40

China’s rare earth industry also features significant government subsidization and tax treatment, which have long been part of Beijing’s strategy.41 Research on the Inner Mongolia Autonomous Region, for example, shows that from 2016 to 2018, “the state’s supporting funds have provided about 4 billion RMB… In this way, the accounting costs of rare earth raw materials for enterprises can be offset.”42

While China today accounts for approximately 70 percent of the world’s rare earth reserves, U.S. and allied dependence is even more acute in the refining of rare earths.43 Even as U.S. companies expand mining capacity domestically, the United States currently has no domestic refining capability.44 By contrast, China controls about 80 percent of global refining capacity.45 Efforts underway to develop commercial partnerships moving downstream toward processing oxides and alloys and producing permanent magnets offer promise. But against this backdrop, Chinese industry analysts dismiss U.S. efforts to expand domestic and allied production and refining capacity. “Don’t worry,” notes one report on global rare earth developments. “After 50 years of development, China has become the dominant supplier, and global reserves have declined.”46 China’s state-owned Global Times similarly called U.S. efforts to improve access to critical minerals “wishful thinking” in 2020.47

Other commentaries point out the weakness of U.S. and allied operations that depend upon Chinese sources for processing, magnet production, and capital. According to one Chinese assessment, projects backed by the U.S. government “contain less heavy rare earths, and their procurement and production costs are still not comparable to those of China.” Thus, the conclusion is that “the future prospects are not promising” for U.S. efforts to offset Chinese rare earth dominance.48 This Chinese confidence is likely bolstered by the reality that at present, capital expenditure and regulatory requirements burden U.S. production facilities with significantly higher costs and longer timelines to reach full operating capacity relative to Chinese peers.

A Path Forward

The U.S. government and private sector and their international partners need to understand the scope of China’s rare earth threat. Building a rare earth supply chain from “mines to magnets” will be insufficient in the face of Beijing’s longstanding and holistic industrial policy. China seeks to leverage its role in related capital markets that support every step of the supply chain. Beijing also prioritizes seizing control of machinery and equipment markets at upstream stages of extraction. And most important, from the Chinese perspective, is China’s dominance in downstream manufacturing of permanent magnets — a role that yields influence over magnet producers and, indirectly, the mines that support them.

Given the scope of China’s positioning, the U.S. government must incentivize and reward private-sector and multilateral investments in wholly independent, trusted supply lines. That independence should apply across sourcing, processing, and financial backing. And the U.S. government should signal resolve in terms of supporting the scope and longevity of such initiatives. Clear public messaging and policy support for trusted critical mineral supply chains are necessary first steps for activating the enduring U.S. advantage of an innovative private sector.

Beijing’s industrial champions enjoy coercive leverage in every significant global market for rare earths, from the United States to Australia and from Greenland to Myanmar. The deficiency of the American response is apparent to our adversaries. Thus, the United States needs to develop both offensive and defensive measures that promote a competitive market and better operational conditions. The U.S. government should adopt an industrial policy that includes stockpiling military-related rare earths, preferential tax policies, and national security and operational security reviews of actors at every stage of the supply chain. Those policies should produce engagement with like-minded democratic allies and partners, such as the United Kingdom, the European Union, Japan, and Taiwan, which face the same supply chain security risks as the United States. Allies and partners with robust extractive industry sectors, such as Australia and Canada, should be prioritized for the unique, trusted contributions they offer to critical rare earth supply lines.

Recommendations

A responsive U.S. strategy should focus on four mutually reinforcing lines of effort:

- defending critical military supply chains through a dedicated and aggressive stockpiling program managed by DoD;

- activating the power of the U.S. private sector through a program of tax incentives legislated by Congress and building upon commitments authorized under the Defense Production Act;

- competing internationally in a strategic fashion under the leadership of the State Department; and

- directly imposing costs on China’s rare earth sector through financial statecraft and military strategy.

The goal should be for the United States to overtake China as the world’s leading rare earth producer and consumer within the next 10 years — matching Beijing’s current pricing power and dominance in the rare earth industry. The immediate task of building a stockpile of military-relevant rare earths will serve as the pacing activity in the lines of effort detailed below. Beyond the immediate and obvious security dividends, this strategy should also produce benefits in terms of technological development, environmental impact, and defense of human rights.

Defending in Depth: Building a Stockpile of Military-Relevant Rare Earths

A necessary — but insufficient — first step to be taken in any worthwhile U.S. rare earth strategy is defensive. The U.S. government must guarantee access to rare earths needed for critical U.S. defense industrial and research purposes. At a minimum, the federal government, operating through the Defense Logistics Agency (DLA) and the procurement authorities of the military services, combatant commands, and other relevant entities across the interagency, should establish a stockpiling program to guarantee supply to major defense acquisition programs (MDAPs). The MDAP portfolio includes DoD’s largest acquisition programs, such as the F-35 Joint Strike Fighter and the Army’s Armored Multi-Purpose Vehicle. This stockpiling effort should start downstream with electric motors and rare earth permanent magnets, with the goal of securing a stockpile sufficient to satisfy demand from MDAPs included in the five-year Future Years Defense Program. After an initial two-year phase, the stockpiling effort should gradually work its way upstream to metal alloys and select rare earth oxides necessary for neodymium magnets. DoD should fund and manage the program covering magnets, alloys, and oxides at specifications required by specific manufacturers and weapons systems, with an expectation to reach initial operational capability by year three and full capacity by year five.

In its initial two-year phase, the stockpiling effort should prioritize domestic supply wherever possible and with consideration for supply partnerships that are economically viable independent of DoD support. After that phase, the program should shift to rigid domestic-content requirements (that is, “buy American” provisions). Relevant oversight committees in Congress should oversee the stockpiling effort and receive quarterly progress updates from the secretary of defense. Once the program reaches an operational capability sufficient to support five years of MDAP demand, it should be briefed to broader congressional and executive audiences on an unclassified basis.

Concurrently, DoD should collaborate with MDAP prime contractors to require similar stockpiling by companies to guarantee domestic control of supplies at the program level. Given the strategic importance of military-specific supply chains and their centrality to strategic competition with China, the United States should pursue redundancy by complementing the government stockpile with a parallel system backed by the defense industrial base. The private-sector stockpile could aim to stockpile enough rare earths to sustain one year of production. This requirement should be included in annual procurement contracts with the U.S. government and should be formally hardwired into MDAP procurements as Key Performance Parameters. The Pentagon’s Joint Requirements Oversight Council should be tasked with reviewing rare earth permanent magnet dependencies in programs that fall below the MDAP threshold. The DLA should be tasked with vetting company-managed stockpiles and should report to congressional oversight authorities annually.

While the DoD and private-sector stockpiling programs are stood up, interim measures will be necessary to address market dependency. The Department of the Interior, the Department of Energy, and the Small Business Administration should form and invest in a rare earth-focused private market investment fund to hedge against and profit from price fluctuations. The Small Business Investment Company model could be pursued for this effort. This fund’s mandate should sunset upon the full realization of the DoD stockpiling program, after which point the proceeds should be returned to the Treasury or converted into a privately owned rare earth element oxide stockpile.

This will be an expensive endeavor. The global rare earth permanent magnet market is valued at over $14 billion per year.49 Collectively, the stockpiling efforts proposed here should be receive an annual budget of over half that value, at a minimum, for a period of five years. China’s current positioning and pricing power will require this outlay if Washington is to overcome Beijing’s near-certain attempts to block U.S. stockpiling efforts. Indeed, this significant investment is necessary to secure the U.S. defense industrial base. New modes of public-private partnership, information sharing, and potential risk sharing may be necessary given that such an ambitious and expedited effort could produce unintended market effects.

Finally, Congress should require the executive branch to submit classified progress reports. Upon attainment of satisfactory benchmarks, Congress should impose domestic-content requirements for future MDAPs, with no consumptive demand exemption loopholes that allow industrial base actors to delay investments necessary for securing their supply chains.

Activating the Private Sector

The U.S. private sector is Washington’s greatest advantage over Beijing. China’s “state-led, enterprise-driven” economic model is adept at applying proven approaches and leveraging scale to accrue leverage across economic interactions. By contrast, the U.S. system’s relative advantage lies not in attempts at top-down control, but in unleashing the creative forces of industry to devise innovative technologies and processes. In the context of critical minerals, opportunities exist at every stage of the value chain for advances to decrease costs, lessen environmental impact, and increase performance. Similar opportunities exist for industry to develop novel solutions — whether in materials science or manufacturing — encouraged by the rewards offered by free-market competition. China’s system is not optimal for seizing those opportunities. But nor is the U.S. government’s current approach. An optimal approach can be found on the factory floor and in the hands of appropriately incentivized U.S. industry.

The United States also possesses a natural resource endowment that should provide a foundation for competitive positioning. That endowment could help provide global pricing power if paired with the U.S. market’s strengths. The power of downstream equipment manufacturers in the United States (for example, in the aerospace, automotive, and medical device industries), along with the power of the U.S. consumer market, could be determinative in reshaping the global rare earth landscape if those producers receive cost-competitive, innovative, and environmentally friendly inputs from U.S. and allied rare earth and critical mineral supply lines. Recently announced investments, such as those by General Motors and Ford, are positive steps toward realizing secure supply chains in key commercial domains.50 Procurement decisions and resource allocations by downstream champions across key industrial sectors should be the guiding metric for U.S. policy aiming to spur on the private sector.

Tax credits can serve as a foundation for government action that can motivate the private sector and encourage development of the domestic supply chain. For example, the Oil Depletion Allowance tax law should be amended so that treatment of rare earth elements qualifies for the highest deductions permitted under Internal Revenue Code 613(b). Additional production tax credits should be authorized for each subsequent link in the supply chain, with prioritization of domestic content, as modeled in the Rare Earth Magnet Manufacturing Production Tax Credit Act of 2021. These credits should not phase out. As with any tax incentive, due diligence will be necessary to distinguish qualified recipients from those seeking to game the system.

In addition, the Defense Production Act (DPA) should be deployed to incentivize rare earth extraction projects in the United States. Rather than executing an ad hoc grant funding scheme, the DLA should use its DPA Title III authority to guarantee purchase of select rare earth oxides needed for neodymium magnets from any U.S.-based mine to satisfy the aforementioned MDAP-focused stockpiling program. This assurance of funding should enable economically viable projects to raise private capital without generating dependence on government support.

DPA Title III funding should also be considered for supply chain nodes where U.S. industry has yet to scale. Immediate targets could include metal alloy development and permanent magnet production. All DPA Title III funding recipients should be required to generate and implement sustainability and recycling programs to mitigate environmental impacts. The targets for such programs should be developed by the Environmental Protection Agency, the Department of Energy, the National Science Foundation, and the Interior Department.

Research and development funding should also play a role. But government funding should focus on application-ready investments capable of achieving commercially relevant scale and sustainability. Ultimately, a combination of robust tax incentives and validated downstream commercial demand will generate private-capital interest in more high-risk research that may generate revolutionary advances. The U.S. government should not aim to pick winners. It should only seed, at a small scale and in a limited set, application-specific cases. The DLA’s recent Small Business Innovation Research solicitation focused on “Development and Qualification of Domestically Sintered Neodymium Iron Boron Magnets for Weapons Platforms” provides an instructive example wherein R&D funds are targeted toward direct, immediate applications. Funding of this nature should increase modestly over the next decade, and the Energy, Commerce, Transportation, Interior, and Defense departments should pursue a more diverse set of funding mechanisms while tax incentives at both the federal and state levels unleash the power of the private sector.

The U.S. government’s approach to activating private-sector forces should also address environmental impacts. The Department of Energy’s Energy Efficiency and Conservation Block Grant Program should be scoped to support state and local efforts that contribute to upstream rare earth production relevant to the automotive industry and broader transportation sector. Moving beyond the two-year milestone of the MDAP stockpiling program, the departments of Energy and the Interior should offer R&D funding to incentivize the U.S. science and technology community to focus on mitigating environmental impacts and supporting sustainable rare earth mining, production, and recycling processes. The environmental impact of rare earth separation and processing should not be ignored, but it also should not be blindly offshored and discounted.

Internationalizing the Competition

Another area of U.S. strategic advantage vis-a-vis China is Washington’s network of allies and partners. The U.S. government should cultivate international partnerships to solve the rare earth challenge.51 This effort should be led by the State Department, which has the requisite footprint and authorities to engage credibly with critical allies and partners. State’s Policy Planning Staff could lead strategic planning for this effort, in coordination with the under secretary for economic growth, energy, and the environment. The department could also leverage the institutional capacities of the Bureau of Energy Resources and the Global Engagement Center. Existing efforts such as the U.S.-Canada Critical Minerals Working Group and the Energy Resource Governance Initiative provide a foundation for partner engagement. The State Department should also leverage its authorities concerning foreign investment and export controls to encourage increased coordination across the interagency as well as with key partners abroad to help protect their strategic resources and technology. The State Department’s international engagement would benefit also from inclusion of U.S. private-sector perspectives and from active coordination with export and overseas investment activities, such as those of the U.S. International Development Finance Corporation.

The State Department must encourage allies with upstream production capacity, such as Australia, to restrict Chinese investment. Greenland stands out as another potential producer that should be courted diplomatically and economically. Key nodes along the supply chain — from equipment for extraction and processing to raw material extraction, alloy processing, magnet production, and recycling — should be identified and supported through multilateral and bilateral engagement. The Critical Materials Institute at Ames Laboratory and the National Energy Technology Laboratory should each be tasked with supporting international partnership development efforts consistent with their research portfolios. And the secretary of state should develop a rare earth supply chain diplomatic strategy to inform resource allocations. Such a strategy can be implemented by interagency actors ranging from the U.S. Agency for International Development to the Commerce Department’s Bureau of Industrial Security.

The U.S. engagement strategy must recognize the markets where U.S. investments redound to China’s benefit. Malaysia stands out as a prominent potential case: While an important contributor to global separation and processing activities, Malaysia’s industrial sector is co-opted by Chinese interests and might need to be jettisoned from U.S. supply chains. Myanmar is a potentially similar case, where complicated diplomatic dynamics demand additional consideration. The Office of the Director of National Intelligence (ODNI) should be tasked with conducting a divestment study focused on the regions, states, and territories where U.S. investments would be ineffective. ODNI should also generate a detailed map of Chinese influence in rare earth supply chains outside China. Risks associated with indirect exposure to Chinese interests in places such as Malaysia and Myanmar should be incorporated into U.S. government vetting of rare earth supply chain security.

On a more tactical level, the U.S. Export-Import Bank should prioritize critical mineral relationships within its China program and its Council on China Competition. U.S. diplomatic efforts should incorporate the critical mineral and rare earth supply chains as key priorities for collaboration with upstream sources as well as downstream partners for rare earth mines, processors, and magnet manufacturers in the United States. Key fora for engagement should include, but not be limited to, the U.S.-EU Trade and Technology Council, the National Technology and Industrial Base system, and the European Raw Materials Alliance.

Imposing Costs in the Market and Through Military Strategy

As Washington achieves a more secure position in rare earths, it must also identify Chinese weaknesses and vulnerabilities that the United States and its allies and partners could leverage.

China wields a robust system of domestic production controls, export management, and both direct and indirect control of overseas production sites to influence global prices and markets.52 The U.S. government can offset these efforts through both market and military maneuvers. For example, the Committee on Foreign Investment in the United States (CFIUS) should prioritize review of Chinese-tied critical mineral investments in the United States, with a focus on the indirect routes by which Chinese capital can secure equity in relevant operations.53 As downstream capacity for production of permanent magnets and corresponding rare earth oxides and alloys expands in the United States, oversight and regulation of the industry should be tailored in line with outbound review frameworks, such as those in the proposed National Critical Capabilities Defense Act.54 Industrial innovations, capacity, and equipment developed in the United States should be protected from both licit and illicit Chinese access in a manner consistent with supply chains in other critical industries, such as the semiconductor industry. Protections against Chinese access should be sequenced so as not to impede near- to intermediate-term progress in defense-specific stockpiling. Eventual implementation of outbound security reviews should follow a transparent system of assessment and waiver consideration similar to the “buy American” provisions in the Infrastructure and Investment Jobs Act, which President Biden signed into law in November 2021.55 Collaboration with democratic allies and partners should similarly prioritize coordination of investment screening and industrial security and intellectual property protection throughout critical minerals sectors.

China’s rare earth industry players should be sanctioned in accordance with relevant Treasury and DoD listing processes and the methodology specified by Section 1260H of the National Defense Authorization Act for Fiscal Year 2021.56 Any subsidiaries or joint ventures connected to these entities should also be delisted from U.S. exchanges in accordance with Executive Order 13959 of November 202057 and should be prohibited from raising capital from public or private equity and debt markets in the United States or from U.S. persons. The U.S. government should use its authority under the International Emergency Economic Powers Act (IEEPA) to seize assets associated with any Chinese rare earth companies that are affiliated with China’s military or military-civil fusion strategy and operate in the United States. These actions should be sequenced to maximize market recognition of U.S. competitiveness and U.S. intent to overtake China in the rare earth sector.

Military and operational national security strategy should also be informed by this ambition. The U.S. military must plan for kinetic scenarios that may introduce risk to critical supply chains. The U.S. military’s power projection capabilities may also serve as valuable tools for cost imposition. The U.S. Air Force’s targeteers should be tasked with generating operational plans for striking key rare earth element extraction sites in mainland China, production facilities associated with China’s rare earth players, smaller extractors that are politically connected in China, key storage depots, and production hubs used for building equipment for separation, processing, and magnet production in mainland China or even under Chinese control abroad. These plans should be developed at a classified level.

The U.S. Navy’s planners should be tasked with structuring exercises focused on interdictions and blockades of rare earth supply lines from external points such as Australia and Greenland. U.S. Army planners should explore similar scenarios involving land-based supply lines of critical minerals and rare earths from Afghanistan and Myanmar. U.S. Special Operations Command should oversee a similar set of exercises focused on disruption of rare earth-relevant facilities in mainland China or under Chinese control and operation abroad. These exercises should be conducted in unclassified settings, with the results briefed to Congress and the executive branch.

U.S. values and democratic norms should permeate America’s rare earth strategy. The State Department and intelligence community should support domestic Chinese rights activists, such as those in Inner Mongolia, who have protested the CCP’s abuse of their local population and environment for the benefit of rare earth extraction or production. The U.S. ambassador in Beijing, for example, could visit these populations or include them in economic- and climate-focused policy events held at the U.S. embassy. The U.S. government should also encourage international fora that amplify the voices of non-governmental organizations that monitor China’s environmental, social, and governance abuses connected to the rare earth industry. Relatedly, the U.S. Customs and Border Protection system should investigate forced labor in Chinese-dominated rare earth supply chains and apply Withhold Release Orders and seizure authorities against Chinese products implicated in prison or forced-labor schemes, which are pervasive in China’s industrial policy support mechanisms.58

Finally, Congress should consider barring the importation of critical materials derived from Beijing’s forced labor regime, by designating them as tied to an emergency humanitarian crisis under Section 307 of the United States Tariff Act of 1930.59 This would follow the precedent set by similar measures enacted in 2010 through the Dodd-Frank Act.60 Congress should also task the Securities and Exchange Commission with requiring that companies listed on U.S. stock exchanges disclose supply chain ties to entities that may be linked to Beijing’s industrial policy that violates human rights norms. Ultimately, increased transparency should motivate downstream consumers in the United States to comply with legal restrictions that target human rights abusers abroad.

Conclusion

The United States possesses the tools and resource endowment to compete with China in the rare earth domain. To do so, America must unleash the power of its private sector. But Washington must also advance a positive technological, environmental, and human rights vision for the rare earth sector. Time is of the essence.

FDD values diversity of opinion and the independent views of its scholars, fellows, and board members. The views of the authors do not necessarily reflect the views of FDD, its staff, or its advisors.